Inhloso

Lesi sexwayiso sokuphepha sigqamisa ubungozi bokwehluleka kwemigqa yokuletha iphampu kakhonkolo okuhlanganisa nokuhluleka kokufakwa ekugcineni.

Amabhizinisi afanelekela okokugcina kumapayipi namapayipi okuletha ukhonkolo kufanele alandele futhi abhale phansi izinqubo zobunjiniyela ezizwakalayo futhi anikeze ulwazi lwezindlela zokuhlola kumakhasimende.

Abanikazi bephampu kakhonkolo kufanele bathole ulwazi kubahlinzeki bamapayipi namapayipi ngezindlela zokukhiqiza ezisetshenzisiwe kanye nezindlela zokuhlola ezifanele.

Ingemuva

Kuke kwaba nezigigaba eQueensland lapho olayini bokulethwa behlulekile futhi bafutha ukhonkolo ngaphansi kwengcindezi.

Ukwehluleka kufaka phakathi:

- ukwehluleka kwepayipi lokulethwa kwerabha

- ukuqhekeka kwesiqu esihlanganayo nesiphetho siyaphuka (bheka Isithombe 1)

- ukuphela kokufaka kuqala ukuhlukana nepayipi lerabha (bheka Isithombe 2) ngokufafaza kukakhonkolo ngaphandle kwegebe.

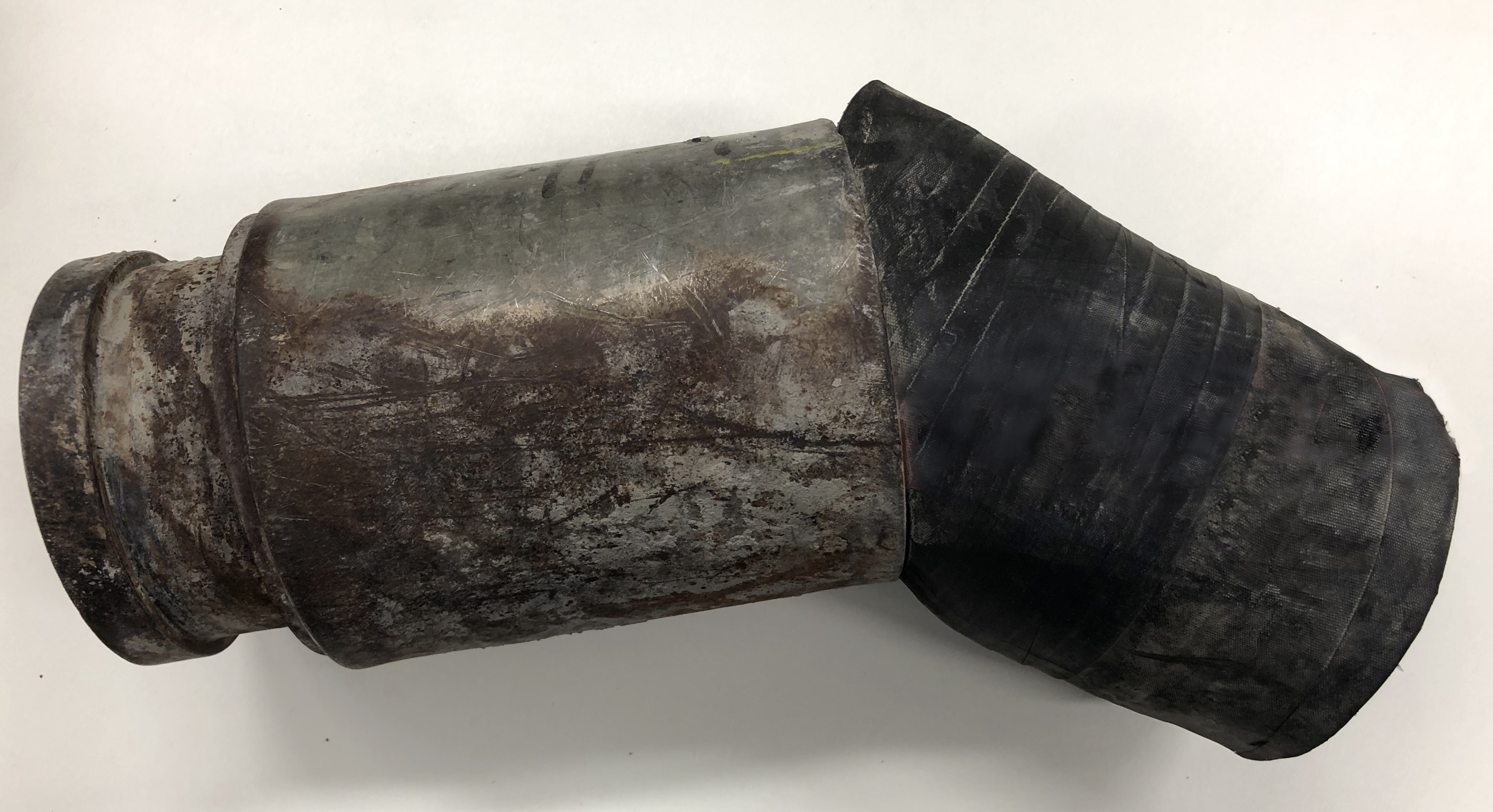

- i-flange eqhekeka futhi ihlukana nensimbi engu-90-degree, 6-intshi ukuya ku-5-intshi enciphisa ukugoba, etholakala ku-hopper (bheka Izithombe 3 kanye no-4).

Ingcindezi yokumpompa ukhonkolo ingaba ngaphezu kwamabha angama-85, ikakhulukazi uma kwenzeka ukuvinjwa. Zonke lezi zigameko zingadala ukulimala kanzima ukube abasebenzi bebeseduze nalapho kwenzeke khona ukwehluleka. Kwesinye isigameko, isikrini semoto saphuka endaweni eqhele ngamamitha angu-15.

Ingxenye ye-hose ephukile futhi ehlulekile

Ukufakwa kokuphela kwe-swaged okuhlukanisiwe nepayipi

I-flange ehlulekile ekujikeni kwensimbi enciphisa

Izici ezinomthelela

Amapayipi nokufakwa ekugcineni kungahluleka ngenxa:

- isilinganiso sokucindezela sepompo likakhonkolo esidlula leso sepayipi yerabha noma okokugcina

- ukubekezelelana okungalungile ezingxenyeni zangaphakathi nezingaphandle zokuhlanganisa

- inqubo yokugudluza noma yokucwila ayihambisani nemibandela yomkhiqizi

- imininingwane engalungile yepayipi lerabha

- ukugqoka ngokweqile-ikakhulukazi engxenyeni yangaphakathi yokufaka kusuka ekugelezeni kukakhonkolo.

Ama-flange kumapayipi ensimbi angahluleka ngenxa:

- ukushisela okungalungile ngenxa yama-electrode angalungile, ukulungiswa okungalungile, ukuntuleka kokungena, noma ezinye iziphambeko zokushisela

- ama-flange namapayipi enziwa ngezinhlobo zensimbi okungaba nzima ukushisela

- ukungafani kahle kwama-flange namapayipi (okungukuthi i-flange ayilingani kahle ekugcineni kwepayipi)

- ukungaphathwa kahle kwe-flange yepayipi (okungukuthi, ukubhodla i-flange noma ipayipi ngesando lapho ipayipi eliseduze kanye/noma i-hose clamp ingaqondile)

- izinsimbi zamapayipi ezingalingani kahle (isb. usayizi ongalungile, ukwakheka kukakhonkolo).

Kudingeka isenzo

Abanikazi bamaphampu kakhonkolo

Abanikazi bephampu kakhonkolo kudingeka baqinisekise ukuthi isilinganiso somfutho wephampu kakhonkolo asidluli leso sepayipi. Isibonelo, uma iphampu ilinganiselwa ku-85 Bar kakhonkolo ngakho-ke akwamukelekile ukuthi ipayipi lensimbi lishintshwe kufakwe ipayipi lerabha elinesilinganiso esiphezulu esingu-45 Bar. Abanikazi kufanele futhi bathathe izinyathelo ezifanele zokuqinisekisa ukuthi uhlelo lokuqinisekisa ikhwalithi luyalandelwa ngenkathi kuxhunywa okokugcina ukuze kugwenywe ukwehluleka kokufakwayo. Ngokuvamile kulula ukuthola isitifiketi kumnikezeli wendawo lapho uthenga okokusebenza.

Uma umnikazi wephampu kakhonkolo engenisa izingxenye ezivela phesheya kwezilwandle, kungase kube nzima kakhulu ukuthola ulwazi oluthembekile ngenqubo yokukhiqiza. Kunjalo lapho umphakeli waphesheya kwezilwandle engaziwa noma lingekho uphawu lomkhiqizi. Abakhiqizi abangathembekile nabo baziwa ngokukopisha amagama abakhiqizi nezimpawu zokuthengisa, ngakho ukumakwa kwemikhiqizo kukodwa kungase kunganikezi ubufakazi obanele bokuthi umkhiqizo ulungele inhloso.

Umnikazi wephampu kakhonkolo ongenisa impahla evela phesheya kwezilwandle uthatha imisebenzi yokungenisa ngaphansi kweUmthetho Wezempilo Nokuphepha Emsebenzini 2011(Umthetho we-WHS). Ongenisa impahla kwamanye amazwe kumele enze, noma ahlele ukuba wenze, noma yiziphi izibalo, ukuhlaziya, ukuhlola, noma ukuhlola okokusebenza ukuze kulawuleke ubungozi bezokuphepha.

Abahlinzeki bamapayipi namapayipi

Abahlinzeki bamapayipi namapayipi anokufakwa ekugcineni kufanele baqinisekise ukuthi uhlelo lokuqinisekisa ikhwalithi luyalandelwa ngenkathi kunamathiselwa okokugcina kanye nokuthi ulwazi kulolu hlelo luyatholakala kumthengi.

Abahlinzeki kufanele futhi banikeze imiyalelo ebhaliwe mayelana nemingcele yokusebenza komkhiqizo kanye nezindlela zokuhlola okufanele zisetshenziswe.

Uma umphakeli enamathisela okokugcina emapayipini noma kumapayipi, umphakeli uthatha imisebenzi yabakhiqizi ngaphansi koMthetho we-WHS ngaphezu kwaleyo misebenzi yabahlinzeki.

Ukufaka ama-fittings ekugcineni kuma-hoses

Ukufakwa ekugcineni kunamathiselwe kumapayipi enjoloba kusetshenziswa izindlela ezimbili, ukugoqa nokuswayiza. Ngendlela ye-crimping, amandla acindezelayo asetshenziswa nge-radially engxenyeni engaphandle (i-ferrule) ye-end fitting nesiqu sangaphakathi esifakwe ngaphakathi ekugcineni kwepayipi. Isiphetho esiqinile singabonwa ngokucacile ngokuhlehlisa okusobala ngaphandle kwesilinganiso sokugcina (bheka Isithombe 5). Ngendlela ye-swaging, ukuphela kokugcina kunamathiselwe ku-hose lapho ukuphela kokugcina kuphushwa ekugcineni kwepayipi ngaphansi kwengcindezi ye-hydraulic. Yize kuzoba nokumakwa okuthile ekugcineni okulingana nenqubo yokukhiqiza, okokufakwa kokuphela kwe-swaged akunawo ama-indent asobala njengokufafa okucijile. Isithombe sesi-2 siyisibonelo sokufaniswa kokuphela kwe-swaged okuhlukaniswe ngokwengxenye nepayipi.

Nakuba i-crimping ne-swaging ihluke ngokuyisisekelo, zombili izindlela zithembele kakhulu ekusebenziseni izingxenye zekhwalithi zokubekezelelana okulungile kanye nokuqinisekisa ukuthi inqubo eqinile yokunamathisela okokugcina iyalandelwa.

Abakhiqizi bamapayipi ngokuvamile bazoqinisekisa kuphela ukuthi ipayipi labo liyakwazi ukumelana nokucindezela okukhonkolo okucacisiwe lapho kufakwa iziphetho zamapayipi ekhwalithi ephezulu. Abanye abakhiqizi bamapayipi basebenza ngaphansi komqondo othi aipheya efanisiwelapho bezoqinisekisa kuphela i-hose yabo ngomfutho omkhulu, lapho kusetshenziswa okokugcina okuvela kumkhiqizi othile kusetshenziswa indlela yokuqinisekisa yokuqinisekisa ukuthi i-crimping noma i-swaging isetshenziswa.

Lapho uhlanganisa ukufakwa ekugcineni kuma-hoses qinisekisa:

- ukuhambisana nayo yonke imibandela eshiwo ipayipi kanye/noma nomakhiqizi wokufaka isiphetho

- impahla ye-hose nobukhulu bufanele ukupompa ukhonkolo kanye nokufakwa kohlobo oluthile lokulinganisa kokuphela

- usayizi wezingxenye zangaphandle nezangaphakathi zokufafa kufanele zibe ngaphakathi kokubekezelela okucaciswe ngumkhiqizi wepayipi noma umkhiqizi wokulinganisa ubukhulu bepayipi elisetshenzisiwe.

- indlela yokunamathisela ukuphela kokugcina kufanele ihambisane nemininingwane yomkhiqizi (ulwazi oluvela kumkhiqizi wepayipi lungadingeka futhi).

Ukuhlolwa kokufaka isiphetho kuyindlela eyodwa yokusiza ukukhombisa ubuqotho bokuxhumana. Ukuhlolwa kobufakazi bakho konke ukufakwa noma ukuhlola okulimazayo kwamasampuli izindlela ezingasetshenziswa. Uma kwenziwa ukuhlolwa kobufakazi, indlela yokuhlola idinga ukuqinisekisa ukuthi i-fitting ne-hose ayilinyazwa.

Ngemva kokunamathiselwa kwepayipi lepayipi, okokufaka kufanele kumakwe unomphela ngolwazi lwenombolo ye-batch kanye nophawu lwenkampani enamathisela isiphetho. Lokhu kuzosiza ekulandeleleni nasekuqinisekiseni inqubo yokuhlanganisa. Indlela yokumaka akufanele ithinte kabi ubuqotho bokuhlanganiswa kwepayipi.

Uma kukhona ukungabaza mayelana nenqubo yokukhiqiza noma ukuhlolwa okuhlobene nokufakwa kokugcina, iseluleko somkhiqizi wokuqala wezinto zokusebenza (i-OEM) kufanele kutholwe. Uma lokhu kungatholakali, kufanele kutholwe iseluleko sikanjiniyela oqeqeshiwe.

Imininingwane ebhaliwe emayelana nendlela yokunamathisela isiphetho kufanele inakekelwe ibhizinisi elinamathisela isiphetho futhi kufanele itholakale uma icelwa.

Welding flanges epayipini lensimbi

Ukushisela ama-flange kumapayipi ensimbi asetshenziselwa ukumpompa ukhonkolo kuyindaba eyinkimbinkimbi futhi kudinga amazinga aphezulu okokufaka kwezobuchwepheshe kanye nekhono ukuze kuqinisekiswe ukuthi inqubo yokushisela izophumela kumkhiqizo wekhwalithi.

Okulandelayo kufanele kuqinisekiswe:

- Ipayipi kuphela elihloselwe ukumpompa ukhonkolo okufanele lisetshenziswe. Ngaphambi kokushisela, kufanele kube nendlela enokwethenjelwa yokuqinisekisa ukuthi ipayipi nama-flange kuwuhlobo lwangempela oluyaliwe.

- Imininingwane ye-weld kufanele ihambisane nezici zempahla yepayipi kanye ne-flange kanye nokucaciswa kwengcindezi yepayipi elishiselwe. Ulwazi kufanele lutholakale kumkhiqizi wamapayipi ngalolu daba.

- I-Welding kufanele ihambisane nenqubo ye-weld enemininingwane ehlanganisa ukukhethwa kwe-electrode, imiyalelo yokushisa ngaphambi (lapho kudingekile) kanye nokusetshenziswa kwendlela yokushisela etuswa umenzi wepayipi.

- Ukwenza ukuhlolwa okulimazayo kusampula yokuhlola ukuze kuqinisekiswe indlela yokushisela ifanele inhloso.

Ukuhlolwa kwamapayipi namapayipi

Abanikazi kanye nabaqhubi bemishini yokupompa ukhonkolo kudingeka baqinisekise ukuthi ukuhlolwa okuqhubekayo kwamapayipi namapayipi kuyenziwa. Izindlela zokuhlola nezikhawu zokulinganisa ukujiya kwamapayipi zichazwe kuIkhodi Yokuzilolonga Yokumpompa Kakhonkolo yango-2019(I-PDF, 1.97 MB). Kodwa-ke, ngaphezu kwalokho, uhlelo lokuhlola kufanele lusetshenziswe ekugcineni ukufakwa kumapayipi enjoloba nama-flange kumapayipi ensimbi.

Ukuhlolwa kwamapayipi

Ulwazi olubhaliwe lokuhlolwa kwamapayipi (okungukuthi kusuka ku-OEM), kufanele lunikezwe ibhizinisi elilingana nesiphetho futhi lokhu kufanele kudluliselwe umphakeli wepayipi kumsebenzisi wokugcina.

Uhlelo lokuhlola kufanele lubandakanye ukuhlolwa ngaphambi kokusetshenziswa kanye nokuhlolwa ngezikhathi ezithile okusekelwe ezikhathini eziningi zokusetshenziswa nendawo yokusebenza.

Uhlelo lokuhlola kufanele lufake:

- ukuhlolwa kwangaphakathi okunamazinga okukhanya anele okuhlola amashubhu epayipi anogqinsi olunengqondo, ayikho indwangu yendwangu noma izinto eziqinisa insimbi eziveziwe, akukho okuvalekile, ukuklebhuka, ukusikeka noma izinyembezi zeshubhu liner, futhi azikho izingxenye ezigoqiwe zeshubhu yangaphakathi. noma ipayipi

- ukuhlolwa kwangaphandle kokuhlolwa komonakalo wekhava okuhlanganisa ukusikeka, izinyembezi, ukuhuzuka okuveza izinto eziqinisayo, ukuhlasela kwamakhemikhali, ama-kinks noma izindawo eziwile, izindawo ezithambile, ukuqhekeka noma isimo sezulu

- ukuhlolwa kokufakwa kokuphela kokuguga ngokweqile kanye nokuncipha kokuqina kodonga

- ukuhlolwa okubonakalayo kokufakwa kokuphela kokuqhekeka. Uma kukhona ukungabaza noma kunomlando wokuqhekeka, ukuhlolwa okungalimazi kungadingeka

- ukuhlola okokugcina akushintshile futhi akusheleli epayipini ngenxa yokuguga noma imithwalo yokudonsa ngomshini.

Ukuhlola ama-flange ashiselwe epayipini lensimbi

Ukwengeza ekuhlolweni kokuqina kwepayipi lensimbi (okucaciswe kwiKhodi yokusebenza) kanye nokuhlola ipayipi elilimazayo, kubalulekile ukuhlola ama-flange epayipi lokumpompa likakhonkolo.

Uhlelo lokuhlola kufanele lubandakanye ukuhlolwa kwalokhu:

- amashisela okuqhekeka, ama-weld alahlekile, ama-weld undercut kanye nokuvumelana kwe-weld

- ama-flanges ukuhlola ukuthi awakhubazekile futhi awanawo amamaki asando

- ipayipi ligcina ngaphakathi ukuze liguge futhi liqhekeke

- ama-flanges ukuze kuqinisekiswe ukuthi awakhiwe ukhonkolo nezinye izinto zangaphandle.

Isikhathi sokuthumela: Aug-07-2021